Author: Yewon Kim, Graphics: Caroline Yee

The BRB Bottomline:

Cultured meat has emerged as the solution to address pressing issues in the meat and poultry industry. Currently, it seems as if lab-grown meat could be the eco-friendly, cruelty-free solution for the average meat eater. In truth, cultured meat faces resource, supply, price, and environmental issues. With all these risks in play, what makes cultured meat so appealing?

Whether at a grocery store, a restaurant, or your own home, meat products are easy to find. The variety and widespread availability of meat products have solidified meat as a fundamental part of the average American’s diet. At a higher, birds-eye view, this importance has led the meat and poultry industry to play a crucial role in fueling the global economy. In the United States, the meat and poultry industry is the largest segment of agricultural production, accounting for $1.02 trillion in total economic output. It alone is responsible for 5.4 million jobs amounting to a cumulative $275 billion in wages, and impacts the lives of many Americans by creating jobs ranging from product packaging to direct distribution. However, this established industry is facing a massive organizational shift with the introduction of cultured meat — a scientific product that appeals to consumers as the sustainable solution to traditional meat.

It All Begins in the Lab

Cultured meat, also known as cultivated meat, is lab-grown animal meat created by cultivating animal cells. The process begins with scientists extracting stem cells from an animal and placing them in a bioreactor, a lab device used to grow organisms under controlled conditions. In the bioreactor, the cells are stored in liquids containing nutrients such as amino acids, glucose, vitamins, and inorganic salts, to help them grow and duplicate. Once enough muscle fibers have grown, the resulting meat cells are harvested and can be manufactured into various types of unstructured meat products, such as burger patties, sausages, and chicken nuggets.

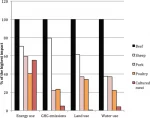

The first lab-grown burger patty was produced in 2013 by Dr. Mark Post at Maastricht University in the Netherlands. The patty consisted of around 20,000 thin strips of muscle tissue and cost over $300,000 to produce over a time span of two years. Following its completion, the product was then showcased at a news conference in London and tasted by food critics, in a culminating moment that showed the world the potential cultured meat had for sustainable food production and consumption. According to Environmental Science and Technology, overseen by the American Chemical Society, the full-scale production of cultured meat would significantly decrease the land, water, and energy used compared to those associated with the conventional method of raising and slaughtering livestock. Furthermore, it would also significantly reduce greenhouse gas emissions in a positive externality for the environment.

With concerns about climate change mounting and now more pressing than ever, an environmentally friendly alternative to producing meat seems exciting and promising for our sustainability efforts. For years, producers of cultured meat have worked to obtain government approval for sales. In December 2020, Singapore was the first nation to approve the sales of a cultured meat product: “cultured chicken,” used as an ingredient in chicken nuggets. The product was made by GOOD Meat, a subsidiary of the San Francisco-based company Eat Just. “This is a historic moment in the food system,” Eat Just’s CEO Josh Tetrick stated in an interview. “We’ve been eating meat for thousands of years, and every time we’ve eaten meat we’ve had to kill an animal — until now.”

Currently, Singapore is the only country that has granted government approval for the sale of cultured meat. However, the United States Department of Agriculture (USDA) has recently funded $10 million to Tufts University to establish a National Institute for Cellular Agriculture to continue developing cultured meat. This support suggests that the U.S. government is behind the movement to transition towards cultured meat, a product that will inevitably arrive to market in the near future.

The “Cruelty-Free” Brand

In addition to it being environmentally friendly, the idea that cultured meat is “cruelty-free” is a prominent argument made amongst its advocates. Cell samples for cultured meat are usually taken from live animals, but under local anesthesia that only causes momentary discomfort, on the level of getting a blood test. Compared to the gruesome events that occur in a conventional slaughterhouse, cultured meat definitely minimizes the terror and pain experienced by livestock.

Even so, while cultured meat is better than conventional meat in many aspects, that is not to say it is a perfect alternative. There are still substantial roadblocks in place preventing cultured meat from gaining critical mass and taking over. “Growth medium” refers to the nutrient-rich solution that allows the extracted animal cells to grow. To produce cultured meat, scientists need an effective growth medium that allows the animal cells to multiply into forming meat in the lab. Fetal bovine serum (FBS) is the most commonly used product, as around 90% of all cells used in cell culture utilize FBS as a source of micronutrients. In particular, FBS is widely used in stem cell research and vaccine biomanufacturing, serving as an important input in understanding and treating diseases. FBS provides the hormones, vitamins, and other growth factors for all types of cells to multiply, as well as buffers against issues like PH changes and endotoxins. In short, FBS gives the good and prevents the bad in the process of cell growth.

This serum seems like the perfect solution to push the production of cultured meat — but instead, it is the biggest obstacle. As its name implies, FBS comes from the blood of a bovine fetus (an unborn calf), and the process leads to the death of both a pregnant cow and the embryo. After a pregnant cow is slaughtered, its reproductive tract containing the fetus is removed from the body. The calf is removed from the tract and its blood is collected, leading to the production of the serum. Over 800,000 liters of FBS are produced every year from the death of 2 million pregnant cows. The production process of this serum serves as the largest challenge for cultured meat producers to stand by the ethical, “cruelty-free” brand they want to espouse. Currently, FBS is a key ingredient in cultured meat that companies have no choice but to use. When Eat Just was approved to sell their cultured chicken in Singapore, an accomplishment hailed as a milestone in the industry, it still used a small amount of FBS in the production.

Scientists are researching and developing alternatives to FBS that do not slaughter animals in the process, which would ultimately increase consumer inclination to purchase cultured meat products. For example, researchers at Nanyang Technological University (NTU) in Singapore are using okara, the leftover pulp from making soy-based foods, to create a growth medium rich in plant growth hormones. Okara is available in large quantities from the food industry, allowing this potential alternative to be sold at a lower price than FBS. Other players are exploring avenues like plant-based serums from algae and even insect-based supplements as ways to replace FBS. However, these alternatives are still under development and regulatory bodies will have to scrutinize them closely before they are released to the public. While the future for cultured meat is looking bright, this bureaucratic hurdle that it must overcome contributes to the delay in it being widely accepted and available in the foreseeable future.

Less Meat, Higher Prices

Compared to the conventional production of meat, the production of cultured meat is a complex, meticulous process that requires sophisticated machinery for scientists to create a precise environment that replicates the growth process of cells in an animal’s body. For example, scientists cannot simply put a small number of cells in a large bioreactor and wait for them to multiply. Cells have precise metabolic requirements for growth, making it necessary to maintain a constant fluid-to-cell ratio. As a result, the fluid has to be pumped into the bioreactor continuously as the cells divide.

The complicated nature of this process is a key reason why the supply of cultured meat is struggling to meet its demand. At a projected cost of $450 million, one hypothetical cultured meat factory would not only be considerably more expensive than a conventional slaughterhouse, but also produce a lot less meat. This hypothetical factory would produce around 10,000 metric tons (22 million pounds) each year. While this may seem like a large number, it is only what a traditional meatpacking plant can produce in just one week. To put it in perspective, this factory’s production only stands for about 0.02% of the 100 billion pounds of meat annually produced in the U.S. Producers of cultured meat must overcome the comparative disadvantage of their substitute good in the market, and cannot yet keep up with the mass consumption of meat.

Furthermore, this comparative disadvantage also leads to unsustainably high prices for the product. The current prices of cultured meat are 100 to 10,000 times higher than that of traditional meat. Research estimates the use of 20,000-liter reactors to result in a production cost of $17 per pound of cultured meat. After markups, this pound of cultured meat would cost $40/lb at the grocery store — compared to the common $6/lb for traditional meat. Because target consumers of cultured meat have cheaper options both currently and for the foreseeable future, price still stands as a clear barrier to entry for cultured meat in a competitive market with established and industry-dominant players. The introduction of cultured meat into the market in and of itself is a work of scientific and logistical genius; however, its supply shortages and high prices relegate it to just being at the moment a novelty good. These roadblocks must be overcome if cultured meat producers wish to persuade meat consumers to stick to their environmentally friendly option in the long run.

A Solution for Beyond Earth

Much of the importance of cultured meat relates to the issue of climate change, as it directly tackles the negative externalities of traditional meat production. However, critics argue that this supposedly environmentally friendly movement is based on scientific inaccuracies and could potentially worsen climate change if production scales up. They reason that the facilities that produce cultured meat will require large amounts of fossil fuel energy to support their machines and technologies — and when considering the massive production of cultured meat needed to meet market demand, the potential environmental impacts suggest that cultured meat may not be as clean or sustainable as proponents claim.

Then, when considering all these disadvantages, why do startups, companies, and investors continue to pour hundreds of millions of dollars into developing cultured meat? There are many unresolved issues with cultured meat, at least on Earth, but maybe not in space. In 2021, the UN’s Intergovernmental Panel on Climate Change (IPCC) released a report that the UN Chief described as a “code red for humanity.” The report explained that unless nations come together to stop burning fossil fuels, tearing down forests, and instead work together to restore the environment, humanity will be faced with a grim, irreversible future on Earth. This bleak reality described in the report has propelled two movements in parallel: cultured meat and space exploration. These seemingly unrelated movements may come together in perhaps an unforeseen way as organizations expand the capabilities of humankind and leverage human ingenuity to open up new possibilities — such as moving to space.

Prominent figures who are leading this idea are billionaires Elon Musk and Jeff Bezos, each with their own aerospace companies. Musk’s SpaceX stands by its mission of “making humanity multiplanetary” by transporting humans to Mars, as well as other destinations in the solar system. Bezos’ Blue Origin carries a vision to create a human society in space to remove damage and preserve resources on Earth, which they call “humanity’s blue origin.” While the two companies may slightly differ in their visions, they both aim to create a habitable environment for humans outside of Earth.

However, in order to sustain life in space, food security is a necessity that needs to be addressed. With the limited resources of water and habitable land in space, how can we continue maintaining our diets outside of Earth? This conundrum gives rise to what could be the true value of cultured meat. In 2019, the startup Aleph Farms went to the International Space Station and successfully produced the first cultured meat in space. In April 2022, Aleph Farms returned to space in a SpaceX rocket and to this day is continuing its research. Cultured meat enables humans to consume meat in space by only having to transport animal cells, as opposed to raising actual livestock. While cultured meat was developed to address issues on Earth, it also has the potential to be a stepping stone for future generations to inhabit space.

For many people, this future of space colonization may seem like a faraway future. Yet, history shows that ideas that seem distant or impossible are often closer than they seem and can actually soon become our reality. Smartphones, AI, and the internet, for example, were all unimaginable just a few decades ago — yet society now revolves around them. If the utility of a product overpowers the costs, then it will inevitably come, whether humankind is on Earth or in space.

Take-Home Points

- The full-scale production of cultured meat would significantly decrease the emissions of greenhouse gasses and the land, water, and energy used in conventional slaughtering methods.

- The complex process of producing cultured meat makes mass production difficult and leads to higher prices compared to factory farm meat, creating a natural barrier to entry.

- Critics argue that cultured meat may not be so environmentally friendly when considering the massive amounts of energy future cultured meat facilities will require to support its machines and technologies.

- The value of cultured meat could lie in addressing food security for future generations that may live outside of Earth by only requiring the transport of animal cells.